What’s in Oquirrh Mountain Compost?

Oquirrh Mountain Compost products are loaded with nutrients and other elements that are good for your grass and plants, all at a price that’s good for your wallet too. Our compost products offer you an attractive medium for your gardening needs.

How are Oquirrh Mountain Compost Products made?

Here’s a little about how the wastewater treatment process works, and how we reuse biosolids and waste wood to make Oquirrh Mountain Compost Products. For more information, visit the Central Valley Water Reclamation Facility website at Cvwrfut.gov

Used water that goes down our sinks, tubs and toilets in our homes and businesses enters the sewer collection system and becomes wastewater. The wastewater from a large portion of Salt Lake County eventually ends up at the Central Valley Water Reclamation Facility. At CVWRF the wastewater is treated to separate and process the liquids and solids, then return them safely to the environment. Because wastewater treatment destroys disease-causing organisms that may be in the wastewater, it protects public health and safeguards water quality, preventing pollution in our lakes and rivers.

Once wastewater flows to the treatment facility, screens and preliminary treatment facilities remove trash and grit materials such as sticks, rags, wipes, plastics, sand and gravel that are harmful to downstream processes. These trash materials are disposed of in the landfill. The wastewater then slowly flows through large primary sedimentation tanks, where gravity physically separates organic solids from liquids. The partially treated water flows from the top of the tanks to a secondary treatment process and the solids that settle to the bottom are removed from the primary sedimentation tanks and enter the solids treatment process.

In secondary treatment, the water passes through trickling filters, aeration basins and secondary clarifiers where the biological action of a culture of beneficial microorganisms removes residual organic solids and dissolved organic matter. The process grows a large quantity of microorganisms, a portion of which must be continuously removed from the system. The waste microorganisms that are removed from the secondary process also enter the solids treatment process.

Finally, the clean water flows through a disinfection process where high intensity UV light is used to inactivate harmful bacteria and other microorganisms before the water is released to the environment. The water is now ready to safely return to Mill Creek and the Jordan River or be treated further for reuse to irrigate the Central Valley Golf Course.

The Central Valley Water Reclamation Facility uses anaerobic digestion and in-vessel aerated static pile (IASP) composting to ensure our composted biosolids is what’s called Class A – Exceptional Quality, EPA’s highest rating, so that our products are completely pathogen free. By using the IASP process, we make sure that our biosolids products are safe, and what’s more, it helps us produce a product that consumers want to use in their yards and gardens. First, in our two-stage anaerobic digestion process, a culture of beneficial microorganisms decompose – or digest – the waste primary and secondary solids at mesophilic temperatures of 98 degrees F. The solids are held in the digestion tanks for approximately 30 days under conditions that exclude all air and oxygen while mixing continuously to promote thorough anaerobic decomposition. This biological stabilization process reduces the solids mass by approximately 50 percent by turning the solid material into methane gas. The methane is collected and burned in large engine generators to produce electricity that powers the wastewater treatment process and heat to warm the digestion process. The anaerobic digestion process also significantly reduces the potentially harmful microorganisms contained in the solids and reduces odors. The anaerobic digestion process is classified in Federal Regulation 40 CFR 503 as a Process to Significantly Reduce Pathogens (PSRP).

The stabilized solids from the digestion process are now called biosolids and are mostly highly degraded organic matter, rich in essential plant nutrients such as phosphorus and nitrogen. We can return biosolids in de-watered form directly to the environment by applying them on agricultural land as a Class B product or use them to produce a higher quality Class A compost product for use by the general public in landscaping and gardening.

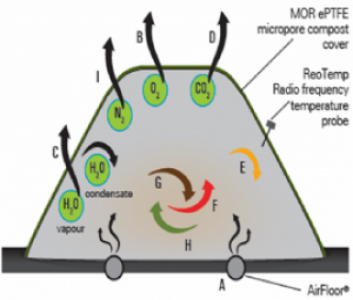

To produce the Class A compost, we use a technology called the in- vessel aerated static pile (IASP) method. This composting method is classified in Federal Regulation 40 CFR 503 as a Process to Further Reduce Pathogens (PFRP). For this method, we mix the dewatered biosolids with ground wood chips and place the mixture in large, covered windrow piles. Photographs of the composting process and sequence are provided below. The windrows piles are built on a concrete pad that contains an air plenum under the pile. Once built, the windrows are covered with a special tarp containing a breathable membrane laminated between two layers of polyester fabric.

The breathable membrane provides a barrier that most long chain molecules, fatty acids, sulfur compounds and other odorous and volatile organic compounds cannot penetrate while air and water vapor can pass through. The tarps and some of the other specialized equipment used in the composting process are supplied by Managed Organic Recycling, Inc. (MOR). More

information about the IASP composting process and equipment used can be found on MOR’s website.

The tarp is sealed against the concrete surface and then air is blown into the air plenum and through the pile to provide oxygen to the composting process. The membrane tarp allows the air to pass through but retains moisture, heat, and odorous compounds which are broken down over time. The temperature of the pile is measured continuously and the air flow adjusted to provide optimum composting conditions. Sufficient heat is produced and retained within the pile by the biological process to heat the pile to greater than 131 degrees F. and kill pathogenic organisms.

Check out our composting process in action!

Here is a step by step of the composting process.